Consult Broshure

Have you faced the down time in an VVF driven/ D.C Drive driven / High Tension Motors due to bearing failure??? If Yes, then we can help you with a cost effective & an efficient solution

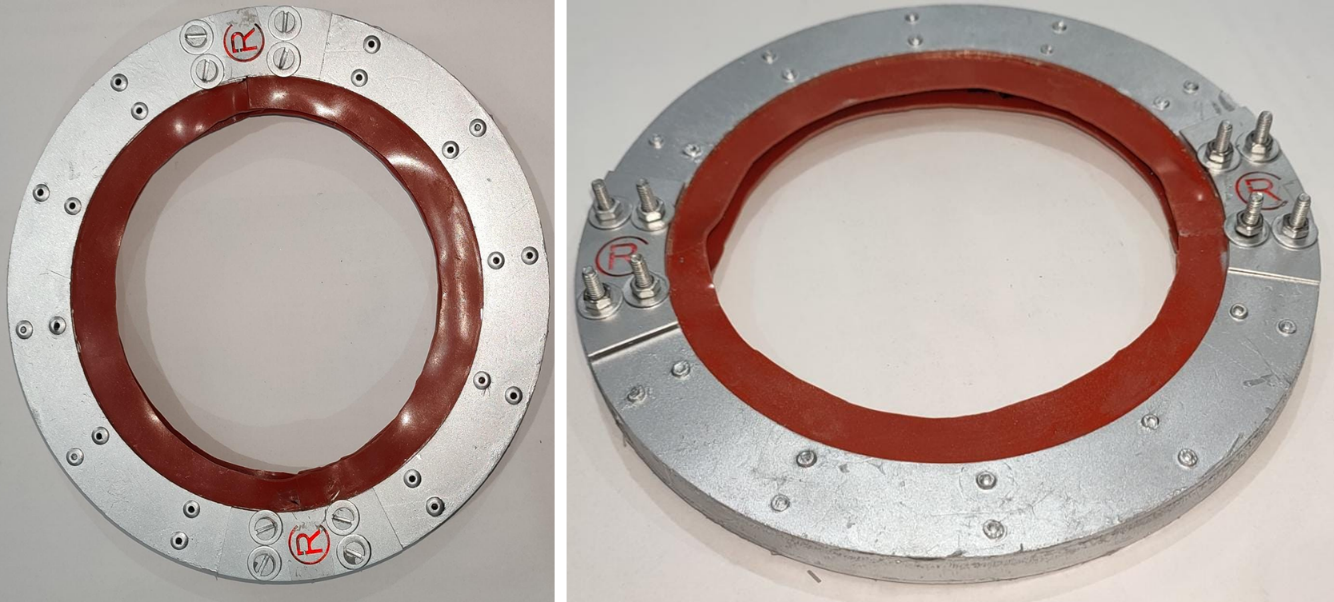

We wish to introduce our company as, Vikyam Private Limited (VPL) and would also like to provide a brief theory as to how Bearing Current Protector (BCP) helps to protect your motor & bearing by diverting current through an alternative path which leads to reduced damage and enhances bearing life. In short, an enhanced Total Cost Ownership of the system. Additionally, it means an Efficient Manpower Utilization as the resource lost in the frequent change of motor of the bearing is nullified.

VPL is a customized technological solution providing company manufactures the state of art BCP, which protects bearing from Motor Rotor Parasitic Current caused through Armature Reaction (DC), Common Mode Voltage (CMV) (AC PWM Drives or HT motor).

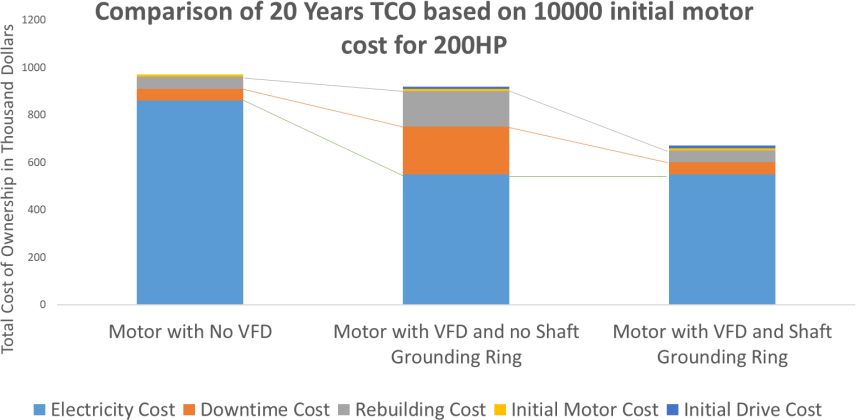

We would like to draw your attention on the benefits in the TCO (Total Cost of Ownership) after the installation of BCPs.

The fig shows a comparison of 10000 numbers of 200HP motors in a span of

20 years with respect to TCO. The graph shows in LHS (Left Hand Side) the motor working with no VFD where the Electricity cost is high and so as to reduce the electricity cost, VFD is procured with an additional cost of initial Drive cost but with a reduction in Electricity cost Rebuilding cost and Downtime cost is increased due to frequent failure of bearing (Motor or/and Load side). The actual advantage of VFD installation is achieved by installing BCP with VFD where the TCO is reduced. Not to mention the manpower and other resources lost with the change of the motor or the Gearbox.

Bearing Failure is one of the major components in a motor due to which downtime occurs, often leading to unreliability of motor performance. As per OEM bearing failure happens due to type or grade of lubrication, Contamination of lubrication, Frequency of lubrication to be applied in bearing. In past several years because of high use of inverter driven motors Bearing failure has increased due to Common Mode Voltage (CMV) current flowing from motor rotor shaft to ground through Bearing. The fig shows bearing failure due to fluting mark on bearing caused by common mode voltage

- The low-Cost solution can be applied to virtually any size AC motor in virtually any VFD application.

- Simple to install & use.

- Lower Impedance Path.

- Low wear & tear rate, Lightweight

- Heat generation is negligible.

- Tests up to 14,000 rpm for 3000 hours.

- Negligible wear & Tear at the lower rotating speeds found in HVAC applications.

- No speed limits.

- Higher current limits over solid carbon brush.

- Large real contact means higher efficiency.

Corona discharge at the tip of the fibres when the fibres are over a charged surface.

About Us

We, VPL are registered under Companies Act 2013 and are based in Navi Mumbai having a vision as Vijayam (Victory) through Ikyam (togetherness) (Vikyam). VPL is a customised technological solution providing company manufactures the state of art BCP, which protects bearing from Motor Rotor Parasitic Current caused through Armature Reaction (DC), Common Mode Voltage (CMV) (AC PWM Drives or HT motor).